In the brief which Dr Tony House gave us it stated that we needed to make a self powered solar powered light which would be robust against outdoor conditions eg salt water, wind and rain . The light also had to turn on at night and off during the day. It also needed to not stand out in the environment.

My light is only 250mm high and 160mm by 160mm wide which should help it from being blown over in high winds, As asked in the brief

I have made the shell of the box out of aluminium as it will not rust with the salt spray and rain and would help to keep my budget down I have made the shell of my box very strong so even if it gets blown over in high winds it will be ok.

I have used LED cluster which will mean that Dr Tony House would not need to waste time putting in new light bulbs as the LED cluster will far out last most standard light bulbs. By using a LED cluster I have gone over my budget of $30 as the LED light was $26 and the big solar panel was $36 but by using this big solar panel it means that the light will recharge the battery even on dark winter days.

I have put the LED cluster inside the box as this will save it from the wind and rain. I have made the sides out of Perspex as it is all low cost and will be ok outside and its far stronger than glass which would get broken if the light was to blow over.

My light has gone over budget a lot but because of this my light is far better than it would have been. I have also sealed it with silicon to help keep out the salt water and rain.

Michael Ballinger 11dtm US 90050

Sunday, November 16, 2008

Tuesday, November 11, 2008

EVALUATION- changes to final design

In the brief from Dr Tony House he stated that we needed to make a solar powered light which would be kept outside in his garden. This means that it has to be robust so it can withstand the wind, rain and most of all salt spray. It has to turn on and off by itself. Dr Tony also asked for a dimmer switch and we only had a budget of $30 to work with.

At first I was thinking about making my light out of stainless steel. But this would have been far to expensive so my next option was aluminium. I decided to use aluminium for lots of reasons one of which is that aluminium is low cost and its easy to work with as it is soft and does not rust so it would meet the brief and look good for a long time.

After deciding about what material to use I came up with the idea of the design for my light and drew it in my book.My teacher gave me the idea of using 4 solar panels but this would not have worked with my idea .I could not use a halogen light as it wouldn't produce enough power to power the battery pack or light. Instead I used a 1w 6v solar panel that completely blew my budget.

I then modified the design of my light to accommodate the solar panel.I also thought of using a 6v lead acid rechargeable battery. After discussing that idea with the teacher we decided not to as it would take up to much space and cost too much and the solar panel would not recharge the battery as it need a charging voltage higher than 6v.So instead I used 4 AA rechargeable batteries in a battery holder which gave me 6v.

To drive the light I modified the circuit that I made earlier in the year by connecting the wires of the 6v circuit which already had a dimmer switch and

a LDR ect. But my idea for what light to use was debated between me and the teacher and so in the end we decided to use a about 1watt LED cluster.

The construction of the shell of the box went well as I had a plan to make it to big so that I would not have to use the cam machine.

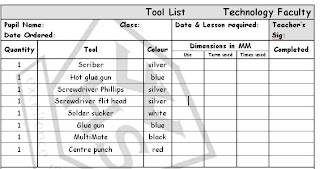

So I ended up scribing out two nets on two different sheets of aluminium which went 100% the way I had planed. Then I used the gulateen to cut where possible. I had to sit down and use a piecing saw to cut out the other bits. To cut out the centre I drilled out lots of holes just inside the outline. Then I used a flat head screwdiver to knock out the bits between the holes

I the filed the sides nice and smooth..

Then it came time for me to make the brackets.I could have used the cam machine for this but I did not as it was giving other people hell. I just marked one out on a strip of aluminium and I centre punched the holes and drilled them out. Then I used this as a template and I made 3 more the same. Then I bent them 90° in the metal bender I drilled holes in the bottom ½ of the box and riveted them on.

Then it was time to cut out the Perspex so I measured out a strip and got someone to help me cut it using the band saw. To get a nice flat line the teacher put it on the belt sander for a bit. It did the job but I would not do it that way next time as the sanded side went all black and (shit) as it melted. Then I cut it into 4 pieces and fitted them to the inside of the box. I drilled out the holes and riveted them on but before that I had to make all the rivets that I used shorter. It took a long time but in the end it gave a far nicer finish.

Then I fitted the circuit and all other wiring and attached the light holder and fitted the top using 2.5 mm self tapping screws. Then I glued on the solar panel with super glue , which did not work. I ended up attaching it with silicone. I then left it to charge up in the sun. When I tested it everything worked the way it should have. I was ready happy with the way it has turned out as a lot of time and work had gone into making work. Next time I would add a cone to the top inside of my box to help make the light reflex more.

Problems encountered:

one of the problems i encountered was that the 6v 1w solar panel would not have power to recharge the lead acid battery which i was going to use

also the 1st circuit i tested which was out of a warehouse light i tested it using the led light and 4AA -6v batterys over heated and just did not work so i used the circuit i made earler in the year

the two nets would not fit in cam machine so had to be cut out using a piecing saw

Michael ballinger 11dtm us 90050

At first I was thinking about making my light out of stainless steel. But this would have been far to expensive so my next option was aluminium. I decided to use aluminium for lots of reasons one of which is that aluminium is low cost and its easy to work with as it is soft and does not rust so it would meet the brief and look good for a long time.

After deciding about what material to use I came up with the idea of the design for my light and drew it in my book.My teacher gave me the idea of using 4 solar panels but this would not have worked with my idea .I could not use a halogen light as it wouldn't produce enough power to power the battery pack or light. Instead I used a 1w 6v solar panel that completely blew my budget.

I then modified the design of my light to accommodate the solar panel.I also thought of using a 6v lead acid rechargeable battery. After discussing that idea with the teacher we decided not to as it would take up to much space and cost too much and the solar panel would not recharge the battery as it need a charging voltage higher than 6v.So instead I used 4 AA rechargeable batteries in a battery holder which gave me 6v.

To drive the light I modified the circuit that I made earlier in the year by connecting the wires of the 6v circuit which already had a dimmer switch and

a LDR ect. But my idea for what light to use was debated between me and the teacher and so in the end we decided to use a about 1watt LED cluster.

The construction of the shell of the box went well as I had a plan to make it to big so that I would not have to use the cam machine.

So I ended up scribing out two nets on two different sheets of aluminium which went 100% the way I had planed. Then I used the gulateen to cut where possible. I had to sit down and use a piecing saw to cut out the other bits. To cut out the centre I drilled out lots of holes just inside the outline. Then I used a flat head screwdiver to knock out the bits between the holes

I the filed the sides nice and smooth..

Then it came time for me to make the brackets.I could have used the cam machine for this but I did not as it was giving other people hell. I just marked one out on a strip of aluminium and I centre punched the holes and drilled them out. Then I used this as a template and I made 3 more the same. Then I bent them 90° in the metal bender I drilled holes in the bottom ½ of the box and riveted them on.

Then it was time to cut out the Perspex so I measured out a strip and got someone to help me cut it using the band saw. To get a nice flat line the teacher put it on the belt sander for a bit. It did the job but I would not do it that way next time as the sanded side went all black and (shit) as it melted. Then I cut it into 4 pieces and fitted them to the inside of the box. I drilled out the holes and riveted them on but before that I had to make all the rivets that I used shorter. It took a long time but in the end it gave a far nicer finish.

Then I fitted the circuit and all other wiring and attached the light holder and fitted the top using 2.5 mm self tapping screws. Then I glued on the solar panel with super glue , which did not work. I ended up attaching it with silicone. I then left it to charge up in the sun. When I tested it everything worked the way it should have. I was ready happy with the way it has turned out as a lot of time and work had gone into making work. Next time I would add a cone to the top inside of my box to help make the light reflex more.

Problems encountered:

one of the problems i encountered was that the 6v 1w solar panel would not have power to recharge the lead acid battery which i was going to use

also the 1st circuit i tested which was out of a warehouse light i tested it using the led light and 4AA -6v batterys over heated and just did not work so i used the circuit i made earler in the year

the two nets would not fit in cam machine so had to be cut out using a piecing saw

Michael ballinger 11dtm us 90050

Monday, November 10, 2008

term 4 week 5 last blog

hello blog for the last time once agent i came in on Saturday and got the light 100 percent done then wot i did was i put more glue on the circuit and dilled out the holes then i used self taping screws to put the bottom plate on i all so put some silicon on to help keep the water out i all so glued the wire to the side and then i put the top on and drilled out the holes and put in the self taping screws then i glued the solar panel on then it was all done then the over time i have been the over time writing my evaluation

Tuesday, November 4, 2008

term 4 week 4

hello blog how are you doing today time is running out fast a lot needs to get done once again i came in on saturday 12-4pm i had to get my big circuit going 1st i had to take out the LEDs and solder to bits wire on then i put more wire on the LDR then add heatshrink on then i added on the battery holder then a put the wires for the solar panel then on tuesday i put the batteries in the holder then glued all the circuit then it was time to go on the over day at lunch time i cut out a bit of aluminium then i screwed it to the box then today i am typing this and adding pics i am all so going to come in the weekend

Subscribe to:

Posts (Atom)